ZTYS640 internal combustion locomotive (dual power)

Operating conditions, technical parameters and main configuration

ZTYS1400 internal combustion traction locomotive (dual power) is our company's patented product, patent number: ZL2010 2 000223694.2, since the product launched into the market has been widely recognized.

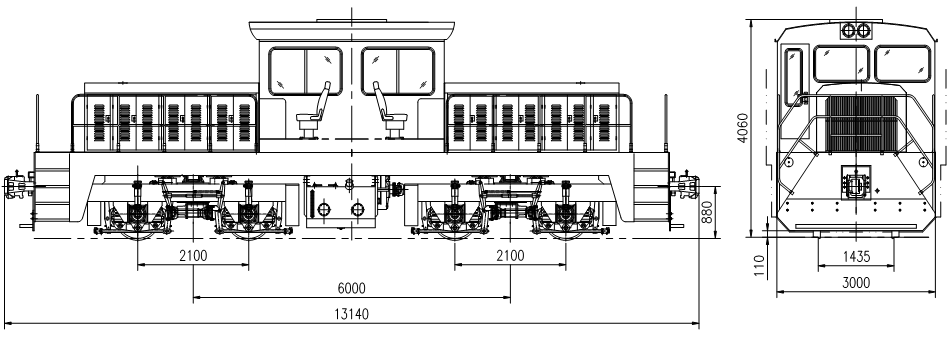

ZTYS640 internal combustion locomotive (double power) is equipped with driver's cab, machine room, frame, power system, transmission system, running gear system, braking system, etc. It consists of two systems of the same power. It can be operated independently by a single engine unit with a power of 320 horsepower/single unit and a maximum traction tonnage of 1,500 tons, or by two units working together with a power of 640 horsepower/double unit and a maximum traction tonnage of 2,500 tons.

一、ZTYS640 internal combustion locomotive (dual power)

In use process, when need drawing large tonnage, two engine unit can work at the same time, the power is: 640 horsepower unit/double, maximum traction tonnage: 2700 tons, when traction small tonnage, single engine unit work alone, its power is: 320 horsepower per single unit, the maximum traction tonnage: 1500 tons, which can satisfy the using condition, but also to reduce fuel consumption, reduce the cost and prolong the service life of the locomotive.

二.Execution standard

1.JB/ t3247-1991 general technical conditions for industrial and mining diesel locomotive

2.TB/ t2494.1-1994 track vehicle axle ultrasonic inspection method

3.GB/ t3314-2006 general technical conditions for diesel locomotive

4.GB/ t3450-1994 "allowable noise value of locomotive driver's cab"

5.TB/ t449-2003 outline of wheel rim tread for rolling stock

6.TB/ t1025-2000 technical conditions for hot coil coil compression springs for rolling stock

7.TB/ t1444-2002 technical conditions for rubber seals for internal combustion engines in vehicles

8.TB/1463-2006 technical conditions for locomotive wheelset assembly

9. Tb1580-1995 welding technical conditions for newly built rolling stock

10.TB/ t2441-1993 technical conditions for assembly of rolling bearing axle box of diesel locomotive

11. TB/T 2817-1997 rolling steel integral vehicle technical conditions for railway vehicles

12.TB/T 2945-1999 LZ50 steel axles and billets for railway vehicles technical conditions

二、Main configuration

The diesel engine Wd615.44g steyr diesel engine

The transmission way Hydraulic transmission

brake Jz-7 brake

Braking way Air brake and hand brake

Coupling type Locomotive no.13 coupler

三、Main technical parameters

power 2x320 hp

Maximum traction 214 kN

Maximum tonnage of traction (straight) 2700 t

A top speed of 30 km/h

Sustained speed 6 km/h

Through the minimum curve radius 60 m

gauge 1435 mm

The wheel diameter 840 mm

The wheelbase 2000 mm

Fixed distance 7200 mm

Axial series B-B

Coupler height 880 mm±10 mm

Preparing a weight About 60 t

Car Length, Width and Height (mm) 13140×3000×3900

四、Main parameters of diesel engine

model | WD615.44G |

Rated power/speed | 235 kW(325hp)/2200 r/min |

Rate of fuel consumption at rated power | 219 g/kW.h |

Generator power | 1000 W |

Air compressor | 0.57 m3/min(2台) |

五、Main parameters of hydraulic torque converter

model | ZTY320型 |

Circular diameter | 409 mm |

六、Hydraulic transmission

Shift control mode | The electro-hydraulic control |

gear | Forward Ⅰ, neutral, backward Ⅰ |

七、Set the main technical parameters of air compressor

type | W-0.9/7-A |

The transmission way | Belt drive |

Exhaust pressure | 0.7 MPa |

Exhaust volume | 2x0.9 m3/min |

八、Towing tonnage list

Traction tonnage meter for single unit

i (The ramp) ‰ | 0 | 3 | 9 | 15 | 21 | 27 | 33 |

speedV(km/h) | Traction weight (t) | ||||||

6 | 1500 | 1058 | 559 | 374 | 277 | 218 | 177 |

11 | 1275 | 724 | 379 | 250 | 183 | 142 | 114 |

16 | 856 | 484 | 249 | 161 | 116 | 88 | 68 |

Twin unit towing tonnage list

i (The ramp) ‰ | 0 | 3 | 9 | 15 | 21 | 27 | 33 |

speedV(km/h) | Traction weight (t) | ||||||

6 | 2700 | 1904 | 1006 | 672 | 498 | 392 | 319 |

11 | 2295 | 1303 | 682 | 450 | 330 | 255 | 205 |

16 | 1541 | 871 | 448 | 291 | 208 | 158 | 123 |

Note: the above traction tonnage table of traction locomotive is the traction weight without curve. If there are both ramps and curves, the traction weight will decrease with the curve radius.

九、Major outsourcing parts supporting manufacturers

NO. | Name and model | Manufacturers, | To address |

1 | Steyr diesel wd615.44g | Hangzhou engine co. LTD | Hangzhou |

2 | Hydraulic torque converter YJ409T1 | Baoji China railway construction machinery co. LTD | Baoji |

3 | Hydraulic continuously variable transmission | Baoji China railway construction machinery co. LTD | Baoji |

4 | Front and rear class I and II drive boxes | Taiyuan heavy industry wheel shaft co. LTD | Taiyuan |

5 | 840 ㎜ grinding wheel steel | Taiyuan heavy industry wheel shaft co. LTD | Taiyuan |

6 | Before and after Ⅰ, Ⅱ driver box | Baoji China railway construction machinery co. LTD | Baoji |

7 | Transmission shaft | Xu chang drive shaft co. LTD | Xuchang |

8 | Locomotive bearing box bearin | Wafangdian bearing | Wafangdian |

9 | JZ-7 Brake/Single | The ministry of railways appoints manufacturers | Shenyang/Tianjing |

10 | Action valve, distribution valve, relay valve | The ministry of railways appoints manufacturers | Shenyang/Tianjing |

11 | Air compressor | Sinotruk/xiamen jaguar | Hangzhou/Xiamen |

12 | Locomotive brake shoe | Baoji China railway construction machinery co. LTD | Baoji |

13 | Electrical control system | Baoji China railway construction machinery co. LTD | Baoji |

14 | Traction device no. 13 upper acting coupler | Shenyang brake machine factory of ministry of railways | Shenyang |

15 | Shock absorption system | Baoji China railway construction machinery co. LTD | Baoji |

16 | Bogie frame | Baoji China railway construction machinery co. LTD | Baoji |

17 | The frame | Baoji China railway construction machinery co. LTD | Baoji |

18 | Car body | Baoji China railway construction machinery co. LTD | Baoji |

十、Quality assurance and technical service

1. The warranty period is one year. The calculation starts after the locomotive is transported to the test and acceptance.

2. The supplier shall be responsible for the reliability, integrity and performance of the locomotive.

3. During the warranty period of the locomotive, the supplier shall be responsible for the defects caused by the design, process and materials of the locomotive and correct them at its own expense.

4. The supplier shall provide free training for the passenger.

5. The supplier shall provide the user manual and relevant technical data free of charge.

6. During the warranty period, if there is any problem with the locomotive, the supplier shall send someone to the site to deal with the problem within 48 hours after receiving the notice from the buyer.

7. Upon expiration of the warranty period, the supplier shall provide technical services free of charge.

ZTYS640 internal combustion locomotive (dual power)

A list of goods to be delivered on board

一、Consumable Part List

NO. | Tool Name | Specification Model | unit | Quantity |

1 | Spare parts for engine | Sets | 1 | |

2 | Brake shoe | Pcs | 8 | |

3 | Safety valve | Pcs | 1 | |

4 | Air switch | 1P6A | Pcs | 1 |

5 | Air switch | 2P30A | Pcs | 1 |

6 | Air switch | 1P20A | Pcs | 1 |

7 | Universal reversing switch | LW5D-16 D0414-2 | Pcs | 2 |

8 | Horn solenoid valve | 3V 210-08 DV24V | Pcs | 1 |

二、Tool List

NO. | names | specifications | unit | The number of |

1 | Box wrench | 5.5×7 8×10 10×12 12×14 14×17 17×19 19×22 24×27 | Pcs | 8 |

2 | Open end wrench | Pcs | 8 | |

3 | Socket wrench | 12.5㎜ The metric system32件 | Sets | 1 |

4 | Adjustable wrench | 300㎜ | Pcs | 1 |

5 | Cutting pliers | 200㎜ | Pcs | 1 |

6 | Screwdriver | “十”字250㎜ | Pcs | 1 |

7 | Screwdriver | “一”字250㎜ | Pcs | 1 |

三、 File List

NO. | Name | unit | Quantity | Remarks |

1 | Locomotive certificate | Pcs | 1 | |

2 | Operating instruction and maintenance manuals | Pcs | 1 | |

3 | Engine document | Sets | 1 |

ZTYS640 internal combustion locomotive (dual power)